Product Details

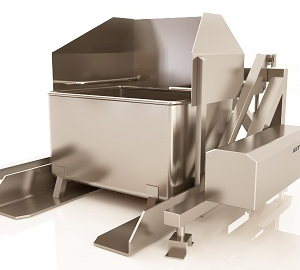

- Eurobin Washing Machine For washing 200 or 300 l buggies. The machine includes a built-in belt filter allowing the constant removal of dirt.

- The machine is steam-heated. Machine corpus made entirely out of stainless steel, material No. 1.4301.

- The machine complies with the high CE-Requirements and EU-and USDA regulations.

- Washing machine for 200L or 300L buggies, electrical heated, PLC S7-120 and Display KP3000

- 1. Machine function

- Designed for washing 200l/300l buggy in DIN 9797 Filter and electrical cabinet are on the left side in direction towards loading the buggy into the machine.

- 2. Technical data

- Capacity: max. 30 pcs/h Siemens Control and Display with program with 9 modes with adjustable times Adjustable washing duration: 2-10 min depending on how dirty the buggies are Rinsing duration: freely adjustable Water temperature for the main washing: 55°C Rinsing water temperature: 85°C /to be provided by the client/

- Water hardness: 6°-7°dH

- Pressure in the water supply pipeline: min. 3 bars

- Inlet orifice for fresh water: R1″ external thread

- Inlet orifice for rinsing water:R1″external thread

- Outlet orifice for waste water:R2″ external thread

- Water tank capacity: 450ltr

- Pump capacity: 62m3/h

- Pump pressure: 3.5bars

- Pump motor power: 7.5kW

- Power supply: 480 V /60Hz

- Degree of protection: IP 65

- Heating: electrical via 2x10kW heaters

- Total power: approx. 28.5kW

- Fuse protection: 35A

- Noise level acc to EN 3418/3419: 84 dB

- Weight: approx. 650 kg

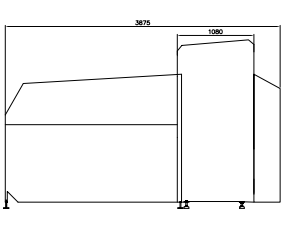

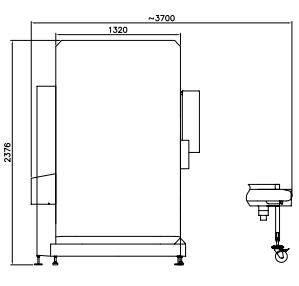

- Dimensions:

- Length without fence and with closed door: 1425mm

- Length with fence: 3900 mm

- Height: 2205 mm

- 3. Execution and operation

- The washing machine is made out of stainless steel material 1.4301. All outside surfaces are polished The hydraulically driven door serves both for loading the buggy and closing the washing machine.

- Once the buggy is inside the machine, push the Start-button to initiate the washing process. The buggy is washed thoroughly on all sides with the help of a stainless steel pump and a rotating arm with nozzles. After the main washing, the machine stops for Pause-1 (adjustable).Then the buggy is cleaned from the remains of the washing solution with clean water (rinsing).Once the buggy rinsing process has been completed, the washing machine stops again for Pause-2 (also adjustable).

- This is a certain period of time for the water to drip off the washed buggy. Once Pause-2 has elapsed, the front loading door opens entirely thus the work cycle is completed and the buggy can be unloaded.

- Connections for chemical dosing equipment 24/220 VAC is provided. New updated model swivel joint.

- The machine is equipped with a cleaning filter to remove the bigger waste from the water and thus prevents it from getting dirty too quickly.

- The filter is mounted on the left side of the machine in direction pushing the buggy into the machine.

- The water from the rinsing flows into the main tank thus not only the buggy is cleaned from the remaining detergent but the water in the main tank is constantly refreshed.

- But this also means that the washing solution is diluted and the detergent-water ratio has to be monitored closely. When the washing process is complete, the door opens automatically and the buggy can be unloaded. If a worker crosses the work zone, the door opening is blocked automatically to prevent injuries.

- Attention:

- In order to guarantee a proper machine function, we strongly recommend that the customer is aware of the cold water quality in the factory.

- The water hardness should not exceed 6° according to the German scale or 1, 25 mmol/l according to the international scale. If the value exceeds this limit, we strongly recommend installing a water softener installation. Otherwise a calcification can cause a total destruction of the heating elements as well as the nozzles and other parts of the machine.

For failures caused by calcification, the machine producer bears no responsibility and the guarantee is not valid.

Additional Information

| Weight | 850 kg |

|---|---|

| Dimensions | 3875 × 2376 cm |

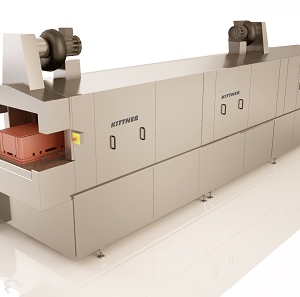

Related products

-

200 / 700 Litre Dual Capacity Chuted Swing Loader

-

Euro Container Pass Through Washing Machine inc Blow Off – 600 Units/hr

-

600 Litre Chuted Swing Loader

Select options This product has multiple variants. The options may be chosen on the product page -

Euro Container Pass Through Washing Machine inc Blow Off – 600 Units /hr